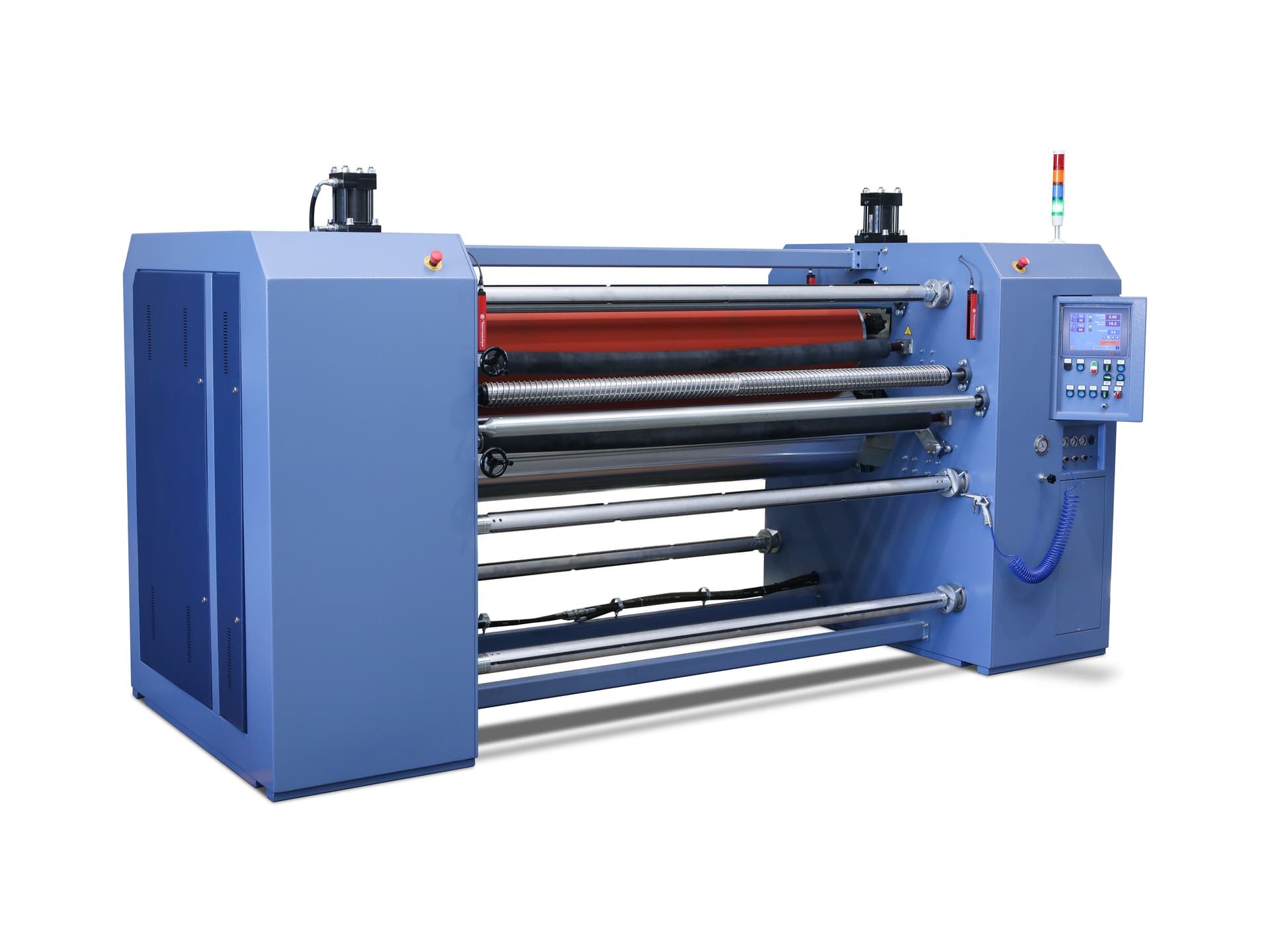

Calender for applying metallic foils and special effects

Printing technology:

Description

LMT 70/40 calenders are designed for the application of metallized foils and special effects:

Heat-transferable films (lacquer, reptile scales, crack, varnish, pull-up, etc.)

sequins, tejus, microdot foils( full or partial lamination) on shuttle fabrics, knitted fabrics and continuous substrates.

Heat bonding and film/web lamination, embossing using release papers, transfer printing of polyurethane, synthetic leather and PVC. Energy-saving mode.

Technical Data

| Dimensioni | 148 × 375 × 236 cm |

|---|---|

| Tipologia | Foil lamination, Continuous printing |

| Dimensione feltro | 200 cm / 78" |

| Tavola utile | 190 cm /75" |

| Cilindro a olio | Ø 40 cm / 15.7" |

| Cilindro a olio superiore in silicone | Ø 40 cm / 15.7" |

| Schermo | 10" digital touch |

| Produttività | High |

| Potenza | 47, 6 Kw |

| Consumo | 19.4 Kw/h |

| Modalità risparmio energetico | 7.14 Kw |

| Pressione | 70 kg/cm² |

| Temperatura | 50°/220° |

| Velocità regolabile | 1 – 15 mt /min |

| Tensione di alimentazione | 400 V 3ph + N |

Specially designed for digital printing on cut pieces and placed prints.

Traditional sublimation printing calender using nomex felt

Designed for digital printing on cut pieces, placed prints, traditional roll-to-roll printing.

Designed for digital printing on cut pieces, placed prints, traditional roll-to-roll printing.

Designed for digital printing on cut pieces and placed prints.

Calender for sublimation printing from transfer paper to synthetic, knitted, nonwoven (tnt), polyester, nylon, and acrylic fabrics.

Inkjet sublimation printing transfer printing calender

Inkjet sublimation printing transfer printing calender

High productivity rotary machines for sublimation printing from transfer paper to synthetic, knitted or nonwoven fabrics such as polyester, nylon, acrylic.

Rotary machines for sublimation printing from transfer paper to synthetic, knitted or nonwoven fabrics such as polyester, nylon, acrylic.

High productivity rotary machines for sublimation printing from transfer paper to synthetic, knitted or nonwoven fabrics such as polyester, nylon, acrylic.

Calender for continuous printing on ribbons, belts, and similar materials

Accessories available

Antistatic bar, banana roller, Cradle winder, Elastic cord enlarger, Faler, Jumbo rewinder, Jumbo unwinder+laser, Motorized unwinder for lycra, Spiral enlarger, Spreader with movable slats, Uncoiler cradle, Upper expansion shaft 400 kg, water cooling shaft

Technical Data

| Dimensioni | 148 × 375 × 236 cm |

|---|---|

| Tipologia | Foil lamination, Continuous printing |

| Dimensione feltro | 200 cm / 78" |

| Tavola utile | 190 cm /75" |

| Cilindro a olio | Ø 40 cm / 15.7" |

| Cilindro a olio superiore in silicone | Ø 40 cm / 15.7" |

| Schermo | 10" digital touch |

| Produttività | High |

| Potenza | 47, 6 Kw |

| Consumo | 19.4 Kw/h |

| Modalità risparmio energetico | 7.14 Kw |

| Pressione | 70 kg/cm² |

| Temperatura | 50°/220° |

| Velocità regolabile | 1 – 15 mt /min |

| Tensione di alimentazione | 400 V 3ph + N |

www.transmaticsrl.com | info@transmaticsrl.com

Via E. Ferrari 9/11/13

20824 Lazzate (MB) – Italy

Via Volta 10

20017 Rho (MI) – Italy

2025 Transmatic S.r.l. All Rights Reserved.

VAT 07282310155 - REA VA 258611 - Share Capital € 101,490.00 i.v.

Our catalog includes a wide selection of presses, calanders, laminators and ovens. A complete range for all types of processing.